Edit

Angevine Machinery and Services Company

Control your investments by optimizing your production equipment.

SAMS

11, 13 rue La Fontaine – ZA La Fontaine

CHAMPIGNE

49330 LES HAUTS-D'ANJOU

+33(0)2 41 41 07 77

Control your investments by optimizing your production equipment.

SAMS

11, 13 rue La Fontaine – ZA La Fontaine

CHAMPIGNE

49330 LES HAUTS-D'ANJOU

+33(0)2 41 41 07 77

SAMS has developed a complete technological solution that facilitates the control of old corrugated cardboard processing machines. Once retrofitted, your machines benefit from reliable, durable electronics, user-friendly and visual control panels via touch screens.

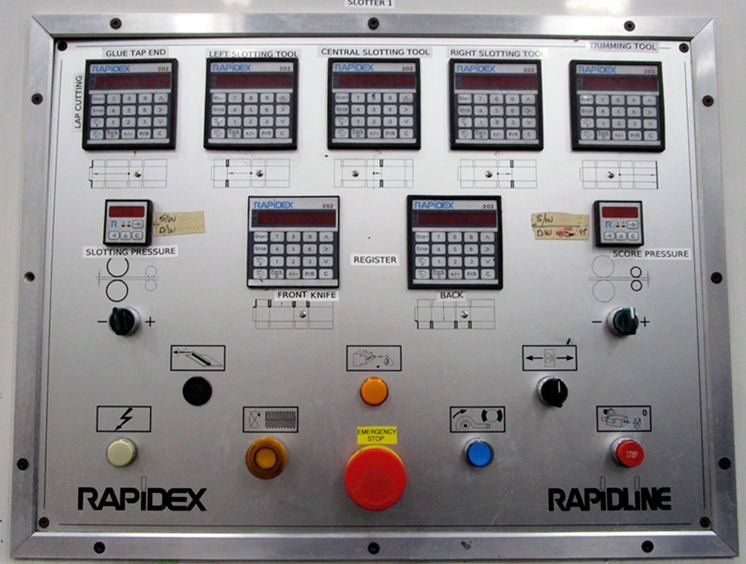

The IVO type NE202 counters, ensuring the management of tool positioning and NE210, ensuring the management of calibrations – thicknesses, were used by many manufacturers of machines intended for the corrugated cardboard processing industry, including Rapidex, for 10 years (1990-2000), but their production is, to date, no longer assured by the manufacturer.

As a result, our company, which specializes in consulting, maintenance and upgrading of these corrugated cardboard processing machines, has studied a complete solution for replacing these meters.

So we can help you guarantee the durability and operational reliability of your machine, as well as greater ease and user-friendliness of programming the controls for your operators. Also, on the calibration axes, we implement absolute encoders, a guarantee of absolute reliability and quality of your machine's settings.

In order to ensure the proper functioning of your equipment, we have carried out a in-depth study of available equipment on the market with the leaders in this field of activity (B&R, Siemens, Rockwell, Allen-Bradley, Schneider and Omron).

Our concern being to ensure maximum reliability, ease of installation and maintenance, our choice therefore fell on the range of products offered by the Austrian company B&R (ABB Group), these guarantee us a very short automation cycle.

Also, in order to make the settings more reliable, we support the automation of the control of your equipment by installing MTS absolute encoders for all the thickness settings (calibrations) of your machine which are currently provided by incremental linear encoders and linear potentiometers, these 2 solutions providing little precision in tool positioning.

B&R Equipment

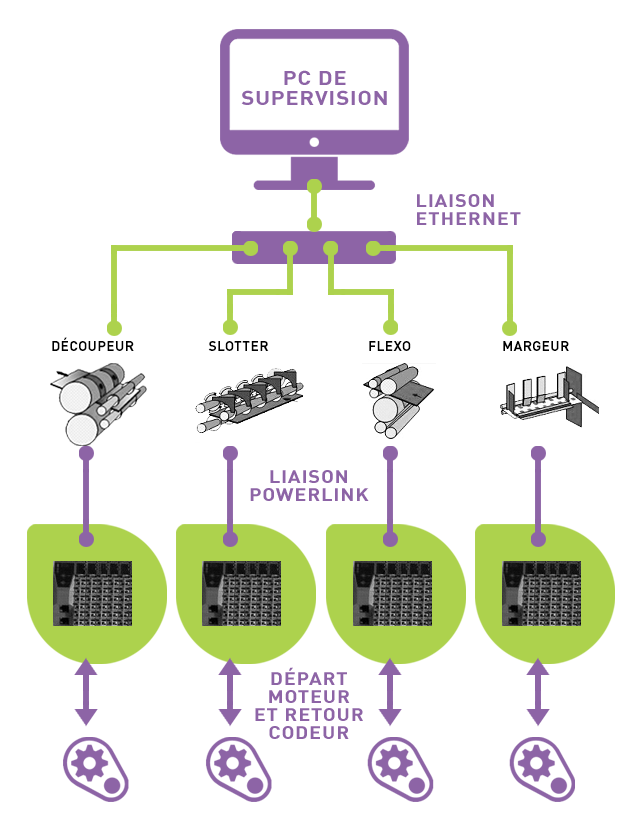

Each module is controlled by a B&R touchscreen PLC, giving you access to various tool adjustment screens and password-protected settings menus, allowing access only to your operators and maintenance personnel.

Online monitoring PC

If your machine is currently equipped with a control PC that is not compatible with the proposed PLCs, we will provide you with a new PC from the DELL Pro range with a screen (supervision software included). Communication is ensured by Ethernet link between the different PLCs and this PC. If your machine is not equipped with this device, a supervision PC will be set up as part of the retrofit.

MTS Coders

MTS encoders are implemented on each thickness setting of your machine. MTS absolute linear encoders have the ability to be insensitive to temperature variations, and even in the event of an unexpected power failure, they do not lose their reference, ensuring instant restart by indicating the exact position dimension during this restart.

We propose to set up a network architecture with a central supervision computer, to which the various corrugated cardboard transformation modules are connected.

Changing operator interfaces

During an automation retrofit, SAMS improves the ergonomics of the control panel. The buttons and faceplates are changed and the interface simplified thanks to touch screen control and its new generation PLCs.