Edit

Angevine Machinery and Services Company

Control your investments by optimizing your production equipment.

SAMS

11, 13 rue La Fontaine – ZA La Fontaine

CHAMPIGNE

49330 LES HAUTS-D'ANJOU

+33(0)2 41 41 07 77

Control your investments by optimizing your production equipment.

SAMS

11, 13 rue La Fontaine – ZA La Fontaine

CHAMPIGNE

49330 LES HAUTS-D'ANJOU

+33(0)2 41 41 07 77

SAMS supports you in the mechanical retrofit of your machines. We have developed technical solutions to prevent premature wear of certain parts (for example, the collapse of the plate cylinder).

Premature wear

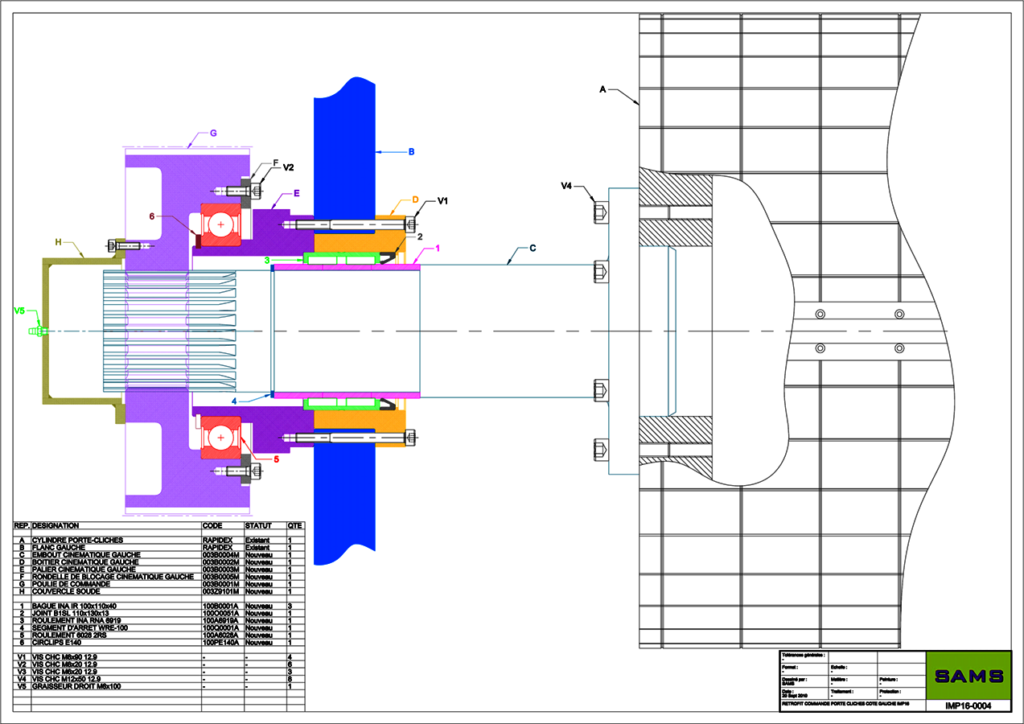

For example, on many corrugated cardboard converting machines, a sagging of the plate cylinder is observed, a notable chronic defect of the 1st generation RapidLine. SAMS has designed a solution to resolve this problem, the left bearing of the cylinder is no longer located at the junction between the cylinder tip and the cylinder itself, but in the side of the module.

Implanted material

This modification requires the complete replacement of all the original elements constituting the kinematics on the left side of the existing assembly.

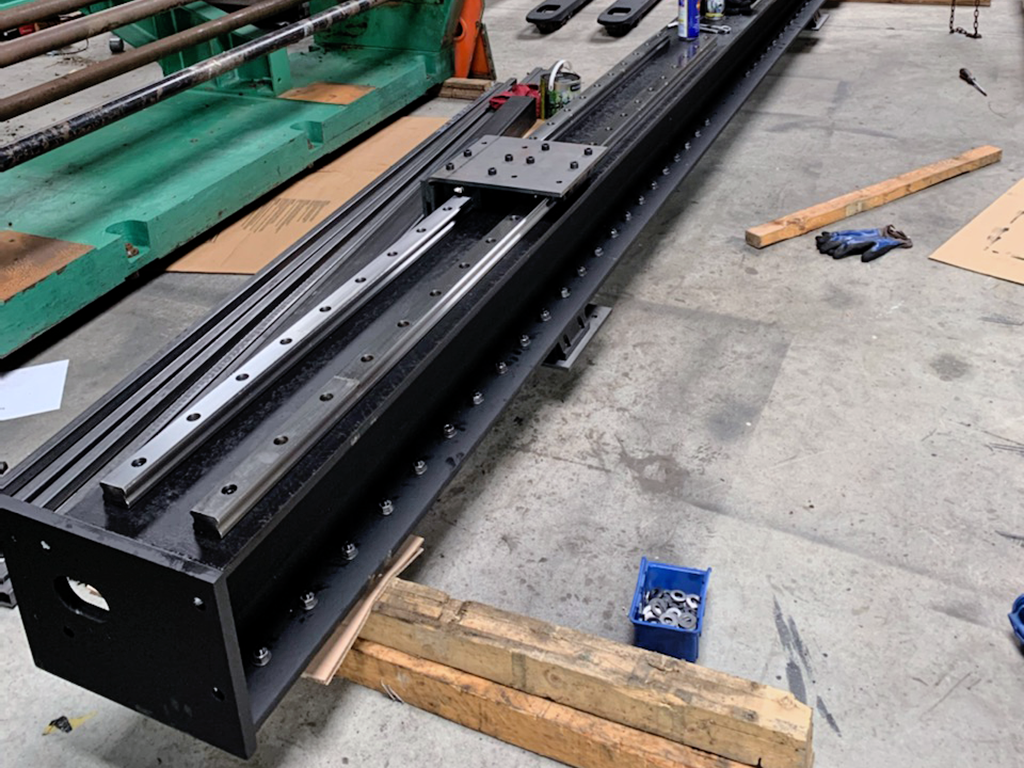

Creation of a stacker beam for a Rapidline 2250 machine.

Installation on the machines is carried out by the SAMS team.